Trusted Twin Screw Extruder Components Manufacturer in Ahmedabad

Unity Engineering Works

As a leading twin screw extruder components manufacturer in Ahmedabad, India, we specialize in high-precision parts that ensure consistent performance and durability. Our product range includes screw elements, kneading elements, conveying elements, spline shafts, screw barrels, and twin screw extruders—all designed to deliver maximum output and efficiency. Whether you need standard parts or custom-designed solutions, we are a trusted supplier and exporter to industries worldwide.

Your Partner in Twin Screw Extruder Excellence

In modern plastic and polymer processing, the performance of a twin screw extruder relies heavily on its core components—screw elements, kneading elements, and screw barrels. At [Your Company Name], we specialize in designing, manufacturing, and supplying these critical parts to meet the needs of industries worldwide. Our precision-engineered components ensure optimal mixing, conveying, and compounding for maximum efficiency and consistent product quality.

- Industry Expertise: Years of experience in designing and manufacturing high-performance extruder components.

- Global Export Reach: Trusted by clients worldwide for superior quality and timely delivery.

- Customization: Tailor-made solutions for specific materials and processes.

- Quality Assurance: Strict quality checks ensure durability and performance.

- Technical Support: Expert guidance from selection to installation and maintenance.

Twin Screw Extruder Components : Engineered for Maximum Performance

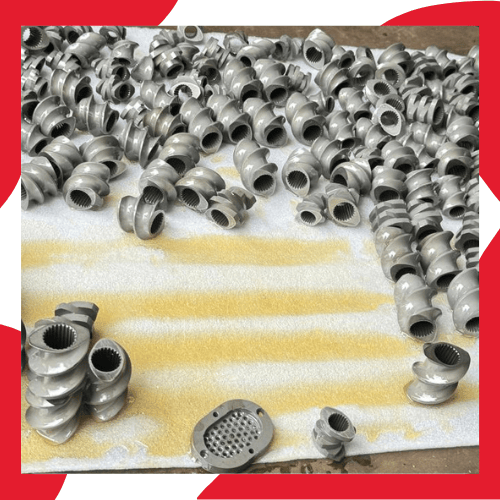

We manufacture and supply a wide range of twin screw extruder components for different applications in plastics, food, chemicals, and pharmaceuticals.

Our screw elements are the backbone of your extrusion process, designed to provide precise conveying, melting, and mixing of raw materials.

Key Features:

- Conveying Elements: Efficiently move materials through the extruder.

- Kneading Elements: Ensure proper mixing and shearing for homogeneity.

- Custom Designs: Tailor-made screw elements for specific materials and processes.

Our advanced manufacturing techniques guarantee high wear resistance, durability, and consistent performance, making us a trusted screw elements supplier and exporter globally.

Our kneading elements play a crucial role in dispersing and homogenizing materials:

Types of Kneading Elements:

- 45° & 90° Kneading Discs: Controlled mixing and shear.

- Forward and Reverse Elements: Optimized material flow.

- High-Temperature Resistant Designs: For advanced compounding applications.

Every kneading element is tested for precision, strength, and performance, ensuring smooth and efficient operation of your twin screw extruder.

Conveying elements are critical for transporting raw materials consistently through the extruder. We manufacture:

- Forward Conveying Elements: Ensure smooth forward flow of polymers.

- Reverse Conveying Elements: Provide back pressure and mixing.

- Special Designs: Customized solutions for unique processing needs.

Our conveying elements are engineered with precision metallurgy, ensuring long service life and stable extrusion.

Our twin screw extruders are built for high-performance processing, ensuring:

- High Torque & Energy Efficiency

- Advanced Mixing & Compounding

- Durable Build for 24/7 Operations

We provide complete twin screw extruders along with custom spare parts, making us your one-stop solution.

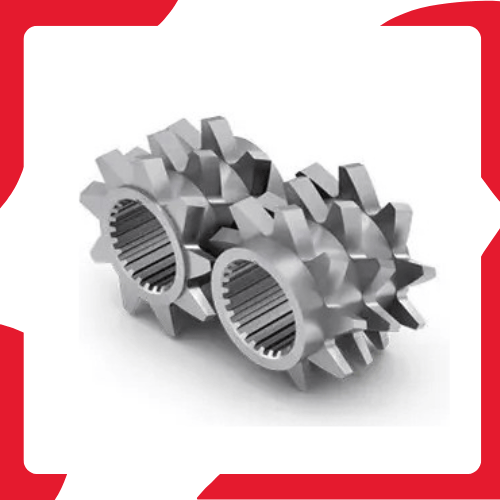

The spline shaft is the backbone that connects elements inside the extruder. We manufacture spline shafts with:

- High-Grade Alloy Steel for strength

- Precision Machining for perfect fitting

- Heat Treatment for durability under high torque

Our spline shafts are trusted worldwide for reliability and long service life.

A high-quality screw barrel is essential for stable extrusion. Our screw barrels are:

- Made from hardened and coated steel for maximum wear resistance.

- Available in various diameters and lengths to fit any twin screw extruder model.

- Designed for easy assembly and maintenance, minimizing downtime.

As a trusted screw barrel manufacturer and supplier, we serve industries including plastics, food processing, chemicals, and pharmaceuticals.

Applications of Our Twin Screw Extruder Components

With our precision-engineered components, your extruder operates more efficiently, reduces downtime, and delivers consistent high-quality output. Our components are widely used in:

At Unity Engineering Works, we engineer solutions for high-performance extrusion. From screw elements to kneading elements and screw barrels, our products are designed for durability, efficiency, and global standards.

Contact Us

Have questions or need assistance? Our team is ready to assist you with orders, product inquiries, or any other requests