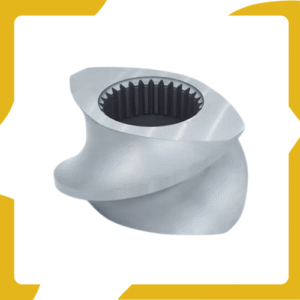

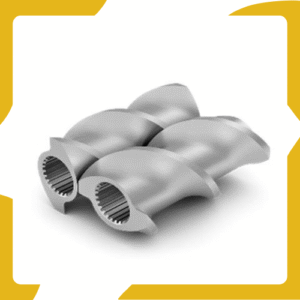

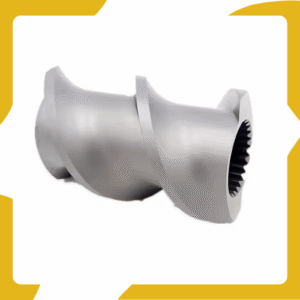

Kneading Elements

Precision-Engineered Kneading Elements for Superior Material Dispersion

As a premier kneading element manufacturer and supplier based in Ahmedabad, Gujarat, India, Unity Engineering Works delivers high-performance kneading elements vital for effective material processing in twin screw extruders. Our precisely engineered kneading elements are designed to achieve superior dispersion, mixing, and homogenization for various polymers and compounds

Kneading elements are crucial components within the barrel of a twin screw extruder, specifically designed to impart intensive shear and elongational forces on the material. This action is essential for achieving excellent dispersion of fillers, pigments, and additives, as well as for melt homogenization and devolatilization. Our kneading elements ensure optimal material treatment, leading to high-quality end products.

Specifications :

kneading Screw Element Processing Characteristics:

- Suitable suggestion on material to ensure components performance and extend lifetime of products.

- Professional technical team can provide surveying and mapping support.

- All components are finished by CNC machine.

- Sophisticated quality managment system ensure superior quality.

- All component materials are supplied by professional material supplier, and element and metallographic analysis are carried out to ensure that the raw materials are safe;

- The internal spline is 100% checked with a spline plug to ensure the interchangeability of the components;

- All components are finished by CNC grinding

- Professional technical team can not only provide timely and accurate sample mapping design, but also provide technical services in component combination.

- The perfect modern management system ensures that the products received by the customers are 100% qualified, and the quality of each component is traceable.

Types of Conveying Screw Elements We Manufacture

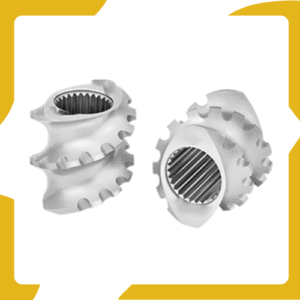

GEAR MIXER, TYPE ZME

Gear mixers are created from a single lobed intermeshing screw problem with recerse design by introducing grooves in the conveying direction of the pitch. This produces a filled up element which mixes intensively distributive.

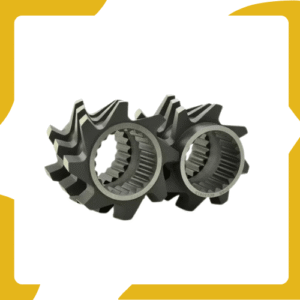

SCREW MIXING ELEMENT SME

The screw mixing element is a two- lobed standard profble screw with reverse-conveying milled recesses in gear format. This element allows for gentle distributive mixing. Very well suited for products that do not tend to form deposits.

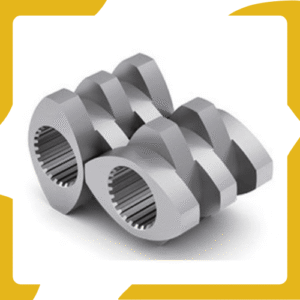

GEAR MIXER BLOCK, TYPE ZB

Gear mixer blocks of the type ZB are created through afternating gear rims on the left & right shaft. It consists with a large degree of variabillity in terms of dimensionning. The teeth can be designed both as forward conveying.

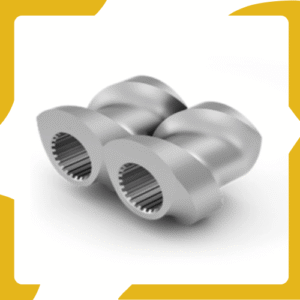

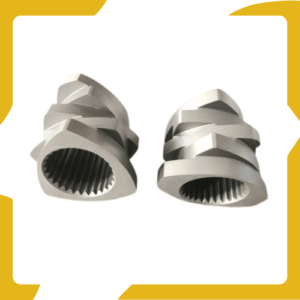

" IGEL" ELEMENT

The “IGEL” element is created from a right-handed and left-handed screw cutting above each other. Mixed dia- mond-shaped spikes are the result. It behaves neutral in regard to conv- eying and is used for distributive mixing. The “IGEL” element is a specialized mixing component in extrusion systems, featuring spiked or toothed geometry .

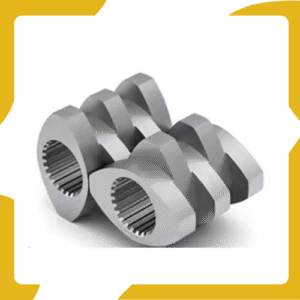

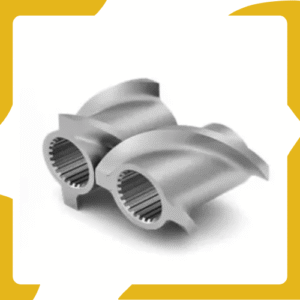

KNEADING BLOCK, NEUTRAL

Standard kneading block in bi-lobed design with tightly inter-meshing profile. The discs are offset by 90 degree so that this kneading block exhibits conveying neutral behavior In a sequence of neutral kneading blocks the degree of falling can thus be influenced well through the process conditions.

SHOULDER KNEADING BLOCK KBS

The shoulder kneading block, type KBS, is a proprietary development from CPM Extrusion Group and has proven beneficial as a standard element in many applications. Through a reduction of the width of the disc in favor of wider overflow areas shearing peaks are reduced and more homogeneous melting results are produced.

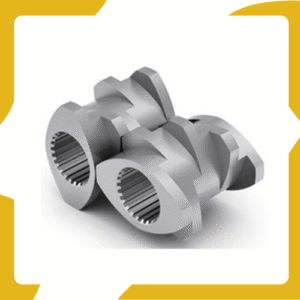

KNEADING BLOCK, REVERSE

Reverse kneading blocks create pressure in order to cause a backup before the element. These kneading blocks lead to a high energy introduction. They are usually designed at lengths smaller than the diameter to prevent the pressure peaks and shear strain in the material from becoming too large.

KNEADING BLOCK CONVEYING

The standard kneading block with conveying design can be constructed both with narrow and relatively wide discs. It exhibits a certain conveying capacity and is partially folled without upstream Flow restriction element. The preferred offset angle is 45 degree; however, versions with 30 or 60 degree.

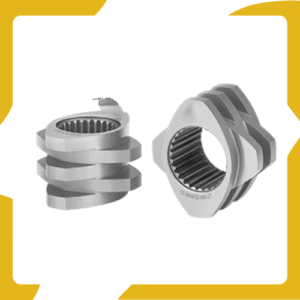

ECCENTRIC TRANSITION KNEADING BLOCK

In a dispersion or melting zone is designed with three-lobed, Y eccentric X kneading blocks of the type KBX a pair of transition blocks, type KBX-A or KBX-B must be installed both upstream and downstream. These elements through the two-lobed starting disk.

ECCENTRIC TRANSITION KNEADING BLOCK

In extruders with the currently popular outside to inside diameter ratios three lobed kneading blocks are only possible with a special prafble. High performance extruders often provide very high driving power. In addition, the eccentric kneading block KBX provides very high melting capacity through high energy input at favorable geometric conditions.

Global Exporter of Kneading Elements

At Unity Engineering Works, quality is paramount in the manufacturing of every kneading element. We utilize high-grade, wear-resistant materials and adhere to stringent quality control processes to ensure the durability and consistent performance of our products. As a trusted supplier and exporter, we provide kneading elements that withstand harsh operational conditions and contribute to the longevity of your extrusion line.

Serving as a reliable exporter of kneading elements worldwide, Unity Engineering Works is committed to delivering exceptional products and support to our global clientele. Our expertise in twin screw extruder components makes us the preferred partner for demanding material processing applications.