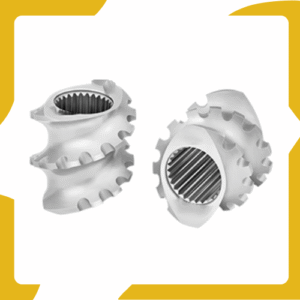

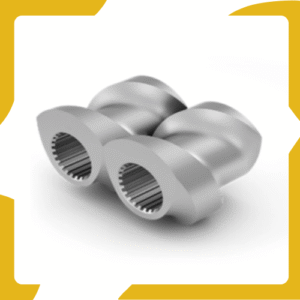

Screw Elements

Screw Elements Manufacturer in Ahmedabad, India

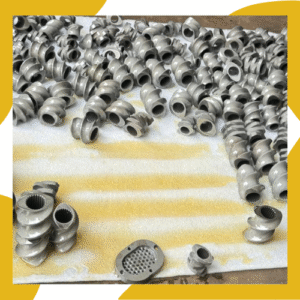

At Unity Engineering Works, we manufacture highly advanced twin screw elements that enhance the overall performance of extrusion processes in mixing, compounding, and material flow control. As a trusted screw elements manufacturer, supplier, and exporter in Ahmedabad, India, we provide customized solutions that help industries improve productivity while ensuring top-class quality.

Screw elements are vital components in precision-driven industries such as plastics, food, pharmaceuticals, and chemicals. They are formed by the assembly of intermeshing, counter-rotating screws that rotate inside a barrel, ensuring proper conveying, melting, shaping, and uniform dispersion of materials.

Types of Screw Elements For Co-rotating Extruders

We provide a comprehensive range of precision-engineered screw elements—including conveying, mixing, kneading, and transition profiles—manufactured under stringent quality control. Each component is designed for global export, supplying major extruder brands with reliability and performance.

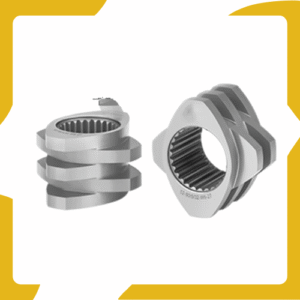

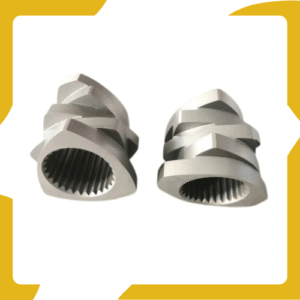

THREE-LOBED CONVEYING SCREW ELEMENTS

The three-lobed conveying element not commonly used in co extrusion lines. The screw element for a divergence ratio of outside diameter to core Damen. A three-lobed conveying element is a mechanical component commonly used in positive.

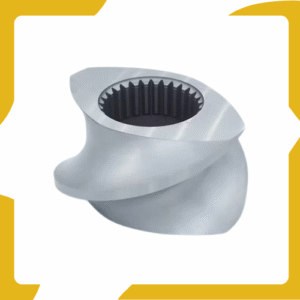

REVERSE SCREW ELEMENTS

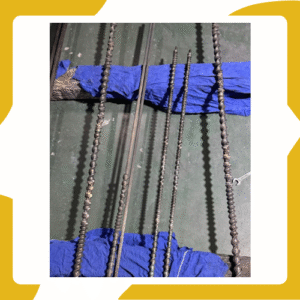

Screw elements with reverse pitch direction are used to generate how restrictions in the melting or mixing zones. They normally have a length of half the outside diameter. NOTE : also available in custom forms (refer to HPE element “single Piece element” on this).

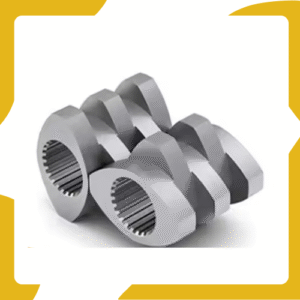

BI-LOBED CONVEYING SCREW ELEMENTS

Bi-lobed conveying elements are used in current twin screw extrudes as standard element for feeding solids. Additionally they melt when pressure is build up before how restricted zones & the discharge. The volume conveying capacity .

BIO-LOBED WITH HIGH SCREW PITCH CONVEYING SCREW ELEMENTS

Tightly intermeshing conveying elements with large pitch are used to pull in and convey also adhering materials. The pitch can be optimised to maximum conveying rate, where the optimum typically line between 1.3 and 2-times the diameter.

SINGLE-LOBE CONVEYING SCREW ELEMENTS

Single lobe conveying elements. because of the wide tip, exhibit a better forced feeding behavior com- pared to two-lobed elements. These elements build up pressure with less energy input & often exercise a sealing function toward the gearbox at the beginning of the screw.

SINGLE-LOBED TO BI-LOBED SCREW TRANSITION ELEMENTS

These transition pieces of the type $12 create a transition between single and two-lobed sealing problem elements without dead spots. They are needed in pairs since the elements for the left and right shaft much be dimensioned directly.

SE YY CONVEYING SCREW ELEMENTS

Conveying element with single-lobe design where YY represents the tip width preferably reduced to the width of the bilobed screws. Is usually employed for relative large pitches in zones where much free conveying volume is required, that is, in the intake area or the area of side feeders and degassing openings.

SE12 TRANSITION SCREW ELEMENTS

These transaction pieces create a continuous transaction between single-lobe elements of the type SEA YY to two- lobed sealing problem elements without dead spots in which product may become deposited. The Transition Element SE12 is typically used in twin-screw extruders to facilitate the smooth changeover .

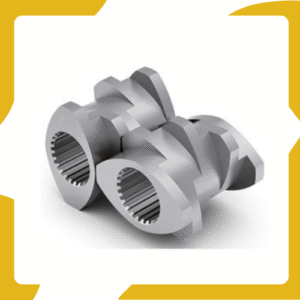

SKK CONVEYING SCREW ELEMENTS

Two-lobed conveying element with two-sided pushing height at relatively large. pitch. This creates a large free conveying volume at simultaneously quite favourable blank angles. These elements can also pull in large volume particles with low density. The Conveying Element SKK is designed for efficient material transport.

BI-LOBED PUSHING FLIGHT SCREW ELELMENTS

Conveying elements in bi-lobed design of the type SK with relatively large pitch where the active, that is the pushing hight features a pushing adge. These elements exhibit a relatively large free volume where the passive hights are cleaned by the nei- bouring elements. The fitting transation pieces have the designation SKN.

Looking For high-performance screw elements Supplier for your twin screw extruder?

Unity Engineering Works is an Ahmedabad based leading Manufacturer, Exporter & Supplier of all Types of Screw Elements. Contact for getting screw element at best price in India