Segment Barrel

Precision-Engineered Segment Barrels for Optimal Extrusion Performance

As a premier segment barrel manufacturer and supplier based in Ahmedabad, Gujarat, India, Unity Engineering Works specializes in producing high-quality, precision-engineered segment barrels crucial for optimal performance in twin screw extruders. Our segment barrels are designed to house rotating screw elements and provide precise temperature control during various material processing applications.

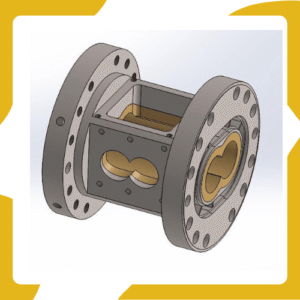

A segment barrel is a vital component in twin screw extruders, forming the main housing for the intermeshing screw elements. Its primary function is to facilitate the conveying, melting, mixing, and devolatilization of materials. Each segment barrel is engineered to provide controlled heating or cooling, creating optimal processing zones for different polymer formulations. The modular design of segmented barrels allows for easy customization and maintenance

Type of segment barrel We manufacture

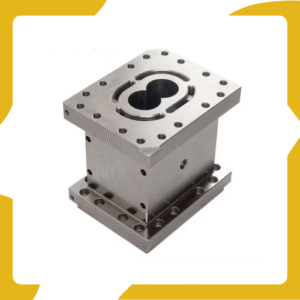

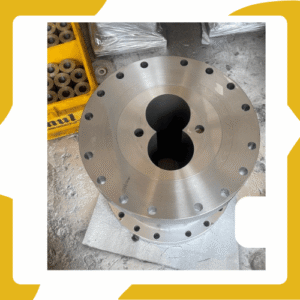

Twin Screw Extruder Segment Barrel

A Twin Screw Extruder Segment Barrel is a modular component that houses the rotating screw elements and provides controlled heating or cooling during material processing. Designed in interchangeable segments, it allows flexible configuration for different processing zones like feeding, venting, or mixing.

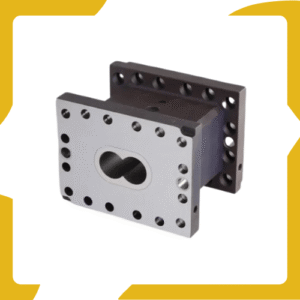

Steel Segmented Barrels

Steel Segmented Barrels are modular barrel components used in twin screw extruders, made from high-strength, wear- and corrosion-resistant steel. Their segmented design allows easy customization of the extrusion process by enabling different functions like feeding, venting, or mixing in separate zones. These barrels offer precise temperature control and are easy to replace or maintain.

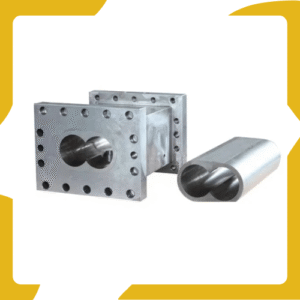

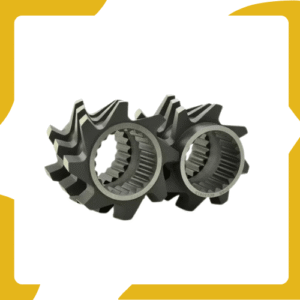

Round Screw Segment Barrels

Round Screw Segment Barrels are circular, modular barrel components used in twin screw extruders to house and guide rotating screw elements. Their round design ensures uniform heat distribution and structural integrity under high pressure and temperature. These barrels are typically made from hardened, wear-resistant steel for durability in continuous operation.

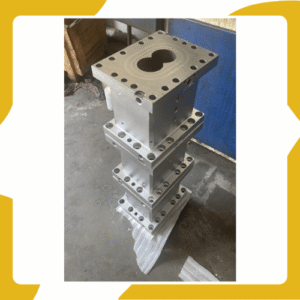

Double Screw Segments Barrel

Round Screw Segment Barrels are circular, modular barrel components used in twin screw extruders to house and guide rotating screw elements. Their round design ensures uniform heat distribution and structural integrity under high pressure and temperature. These barrels are typically made from hardened, wear-resistant steel for durability in continuous operation.

Plastic Extruder Screw and Barrel

Plastic Extruder Screw and Barrel are core components of an extruder, working together to melt, mix, and push plastic material through a die. The screw rotates inside the barrel, conveying and compressing the plastic pellets while generating heat for melting. The barrel provides a heated, controlled environment to ensure uniform melting and processing.

Screw Segment Barrel for Parallel Twin Screw Extruder

A Screw Segment Barrel for Parallel Twin Screw Extruder is a modular barrel designed to house and support the parallel, co-rotating screws in twin screw extruders. Made from hardened, wear-resistant steel, it ensures precise screw alignment and efficient heat transfer. The segmented design allows customization for different processing zones like feeding, melting, and venting.

Global Exporter of segment barrel

At Unity Engineering Works, our commitment to quality is unwavering in the manufacturing of every segment barrel. We utilize high-grade materials and adhere to stringent quality control processes, ensuring the durability, wear resistance, and consistent thermal performance of our products. As a trusted supplier and exporter, we provide segment barrels that contribute to the longevity and efficiency of your extrusion lines.

Serving as a reliable exporter of segment barrels worldwide, Unity Engineering Works is dedicated to delivering exceptional products and support to our global clientele. Our expertise in twin screw extruder components makes us the preferred partner for demanding material processing applications, ensuring your operations run smoothly and efficiently.