Conveying Elements

Precision-Engineered Conveying Elements for Twin Screw Extruders

As a leading conveying screw element manufacturer and supplier based in Ahmedabad, Gujarat, India, Unity Engineering Works specializes in producing high-performance conveying elements crucial for efficient material handling in twin screw extruders. Our precision engineered conveyor screw elements are designed to optimize the transport, mixing, and processing of various materials in demanding industrial environments.

The conveying screw component is mainly a thread structure, and its function is to convey the material and give the material a certain thrust so that the material can overcome the resistance encountered in the flow channel. Conveying screw elements are currently the most popular extruder screw elements, with a strong transport function, short residence time and good self-cleaning properties.

Specification:

Processing Characteristics of UNITY Extrusion Screw for Sale

- Suitable suggestion on material to ensure components performance and extend lifetime of conveying screw components.

- Professional technical team can provide surveying and mapping support.

- All extrusion screws are finished by CNC machine.

- Sophisticated quality managment system ensure superior quality.

- All extruder screw component materials are supplied by professional material supplier, and element and metallographic analysis are carried out to ensure that the raw materials are safe;

- The internal spline is 100% checked with a spline plug to ensure the interchangeability of the conveying screw components;

- All twin screw extruder screw elements are finished by CNC grinding

- Professional technical team can not only provide timely and accurate sample mapping design, but also provide technical services in component combination.

- The perfect modern management system ensures that the conveying screw elements received by the customers are 100% qualified, and the quality of each component is traceable.

Types of Conveying Screw Elements We Manufacture

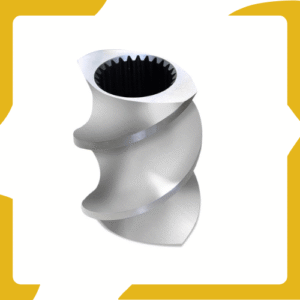

Screw Conveying Element

A Screw Conveying Element is a key component of twin screw extruders, designed to transport materials along the barrel through a rotating screw mechanism. It typically features helical flights that move bulk materials forward while enabling controlled mixing and compression. Made from wear-resistant steel, these elements ensure durability under high temperature and pressure.

PCS70 Conveying Screw Element

The PCS70 Conveying Screw Element is a precision-engineered component used in twin screw extruders for efficient material transport and processing. Designed with a 70 mm screw diameter, it features helical flights that move materials forward while ensuring consistent flow and pressure. Made from high-strength, wear-resistant materials, it offers durability in high-temperature.

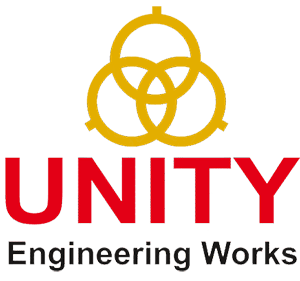

Mixing Screw Element and Conveying Screw Element

Mixing Screw Elements and Conveying Screw Elements are essential components of twin screw extruders, each serving distinct functions. Conveying elements are designed with helical flights to transport materials along the barrel efficiently, ensuring consistent flow and pressure. Mixing elements, on the other hand, have special geometries.

Twin Screw Extruder Conveying Element

A Twin Screw Extruder Conveying Element is a helical screw component designed to move materials efficiently along the length of the extruder barrel. It ensures consistent material flow, pressure buildup, and controlled residence time. These elements are modular and can be arranged to suit specific processing needs.

Single-Fighter Conveying Screw Elements

Single-Flight Conveying Screw Elements are fundamental components in twin screw extruders, designed with a single helical flight to transport materials steadily along the barrel. They provide smooth conveying action with low shear, making them ideal for feeding and melting zones.

CONVEYING ELEMENT SKK

Two-lobed conveying element with two- sided pushing height at relatively large. pitch. This creates a large free conveying volume at simultaneously quite favourable blank angles. These elements can also pull in large volume particles with low density. The Conveying Element SKK is designed for efficient material transport.

Global Exporter of Conveying Elements

Unity Engineering Works is a trusted supplier of conveying elements for a wide array of industries, including plastic compounding, masterbatch production, and various polymer processing applications. As an experienced exporter, we ensure that our high-quality conveying elements reach clients globally, providing reliable solutions for their extrusion machinery