Twin Extruder

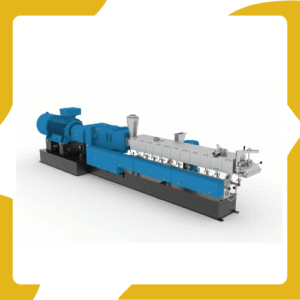

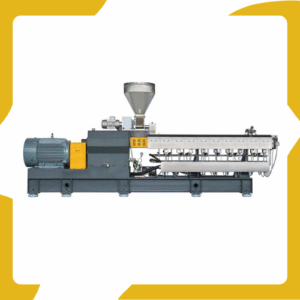

UNI-H Series Twin Screw Extruder

The UNI-H Series Twin Screw Extruder is a high-performance, co-rotating intermeshing extruder widely used in plastic compounding, masterbatch production, and polymer blending. It features a modular screw and barrel design for flexibility in processing various materials. Known for high torque and precise temperature control, it ensures efficient mixing, dispersing, and devolatilization.

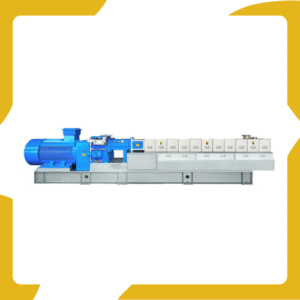

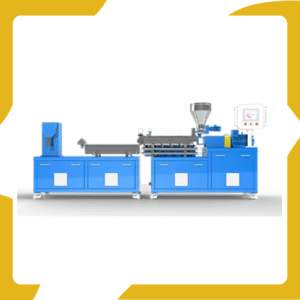

UNI-Twin Screw Extruder

The UNI-Twin Screw Extruder is a lab-scale, co-rotating intermeshing extruder designed for research, development, and small-batch production. With a 20 mm screw diameter, it offers precise control over mixing, compounding, and processing of polymers and additives. Its modular screw and barrel design allows flexibility for different formulations. Ideal for testing materials before scaling up to larger systems.

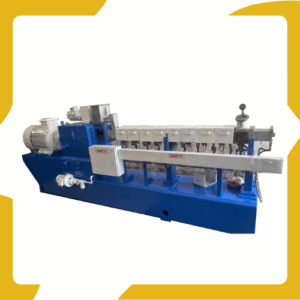

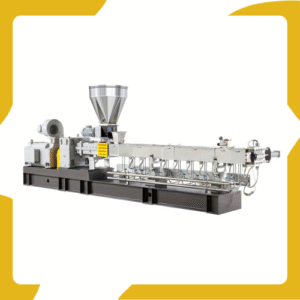

UNI-Twin Screw Extruder

The UNI-Twin Screw Extruder is a cost-effective, co-rotating intermeshing extruder designed for general-purpose plastic compounding and masterbatch production. It features a robust design with good mixing efficiency and stable performance. Suitable for medium-output applications, it offers a balance of performance and affordability. The UNI-TWIN is ideal for processors seeking reliable operation with lower initial investment.

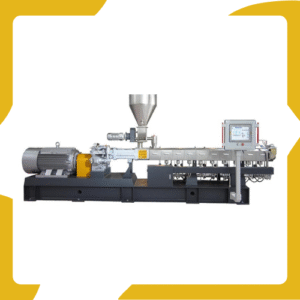

UNI-Twin Screw Extruder

The UNI-Twin Screw Extruder is a high-torque, high-output extruder designed for demanding industrial applications such as engineering plastics, high-filled compounds, and reactive extrusion. It features an advanced gearbox, modular screw and barrel design, and precise temperature control for efficient processing. The UNI-TWIN supports large-scale production with excellent mixing and dispersing capabilities.

Counter Rotating Twin Screw Extruder

A Counter-Rotating Twin Screw Extruder features two screws that rotate in opposite directions, commonly used for PVC processing, profile extrusion, and pipe production. It provides excellent material compression and shear control, making it ideal for heat-sensitive materials. These extruders are available in intermeshing and non-intermeshing types, offering stable output and consistent product quality. They are widely used in both rigid and flexible PVC applications.

Twin Screw Pipe Making Machine

A Twin Screw Pipe Making Machine is specifically designed for producing plastic pipes, commonly using materials like PVC. It typically uses a counter-rotating twin screw extruder for stable output and uniform plasticizing. The machine includes components like a die head, vacuum calibration tank, haul-off unit, and cutter for continuous pipe production. It ensures precise dimensional control and smooth pipe surfaces, ideal for water supply.